PET Strapping Band Extrusion Line

Description

Preface: The current technology of PET packaging strap enables production with 100% recycled material, which is in line with the policy of environmental protection around the world. Its cost is more than 30% lower than that of steel strapping. It also has the advantages of having fine appearance, does not rust, has good impact resistance, and is safe and convenient to use. It is expected to overshadow the steel strapping market and even the PP polypropylene strapping market in the near future. Currently, the PET packaging strap market is experiencing rapid growth.

Our team’s competitive edge lies in our threefold capability of mastering production technology, sales channels, and manufacturing equipment, which means the ability to provide all-round systematic and professional services with a deep understanding of market demand. Traditional equipment manufacturers can only manufacture equipment; they do not understand product manufacturing and marketing.

In contrast, our team attaches great importance to innovation, research, and development, as evidenced by the grants and innovation awards we have received for years from the government. We are striving to constantly improve our raw materials upgrading technology and product quality stability in order to develop Super High Strength PET Strapping

Project No. 130509

Small and Medium Enterprises Innovation Service Certification Supportive Program, “100% Recycled PET Toughening and Upgrading Technology”

Project No. 130509

Small and Medium Enterprises Innovation Service Certification Supportive Program, “100% Recycled PET Toughening and Upgrading Technology”

Contract number E10300018005-302

Science and Technology Research and Development Program sponsored by the Ministry of Economic Affairs for Conventional Industry Technology Development (CITD): “Product Development Plan of Recycling Using PET to Produce High Tensile Packaging Strap”

Contract number E10300018005-302

Science and Technology Research and Development Program sponsored by the Ministry of Economic Affairs for Conventional Industry Technology Development (CITD): “Product Development Plan of Recycling Using PET to Produce High Tensile Packaging Strap”

Description of Package Plant Export Equipment Manufacturing

Raw material ingredients/mixtures

Raw material ingredients/mixtures

-

-

-

Raw material drying system

-

-

-

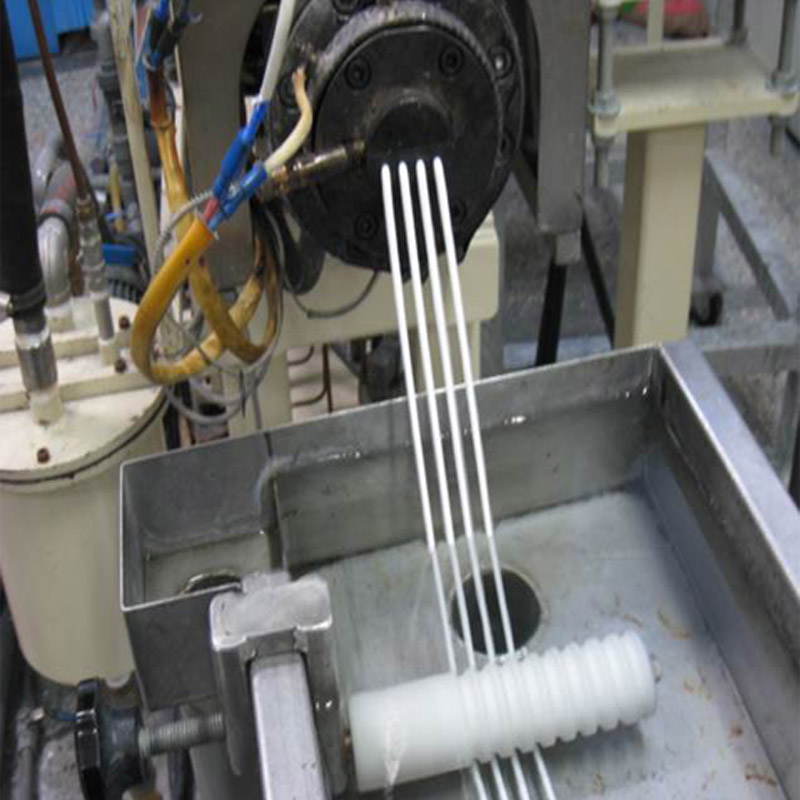

Multi-sectional extension

-

-

-

Strapping winder

-

-

-

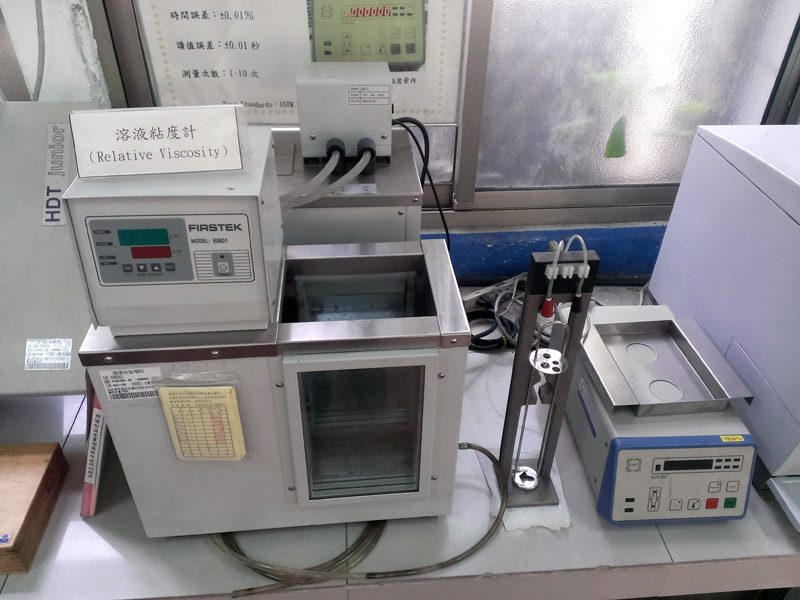

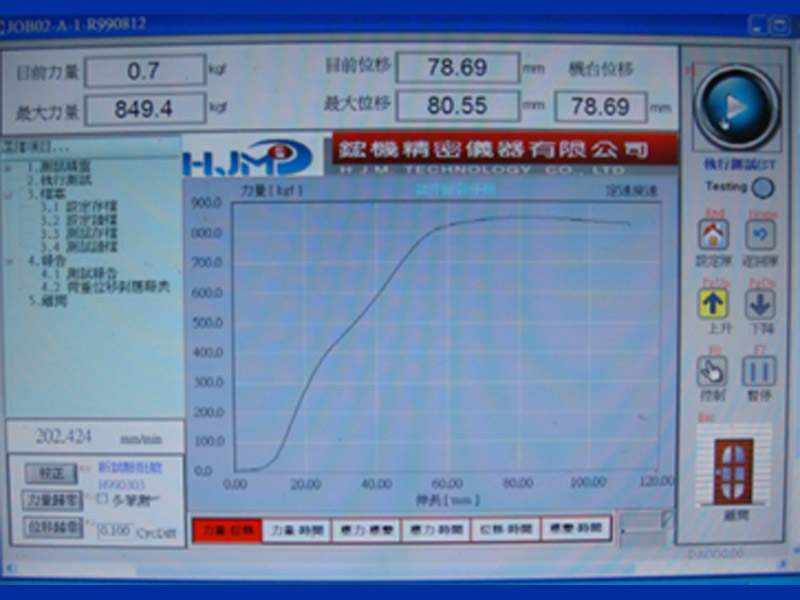

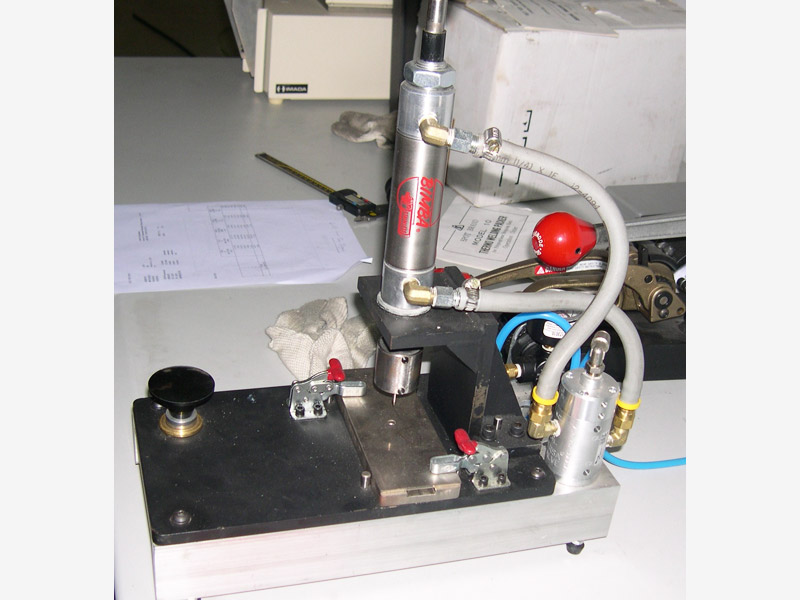

Quality inspection

-

-

-

-

-

-

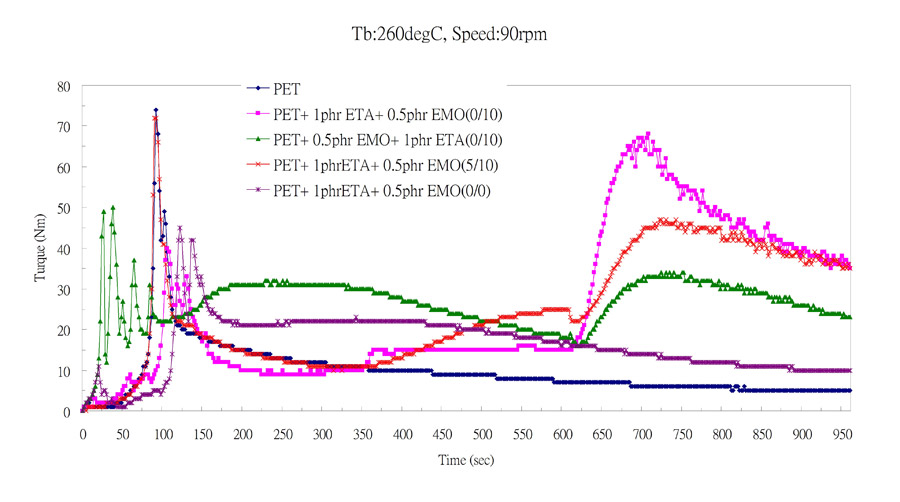

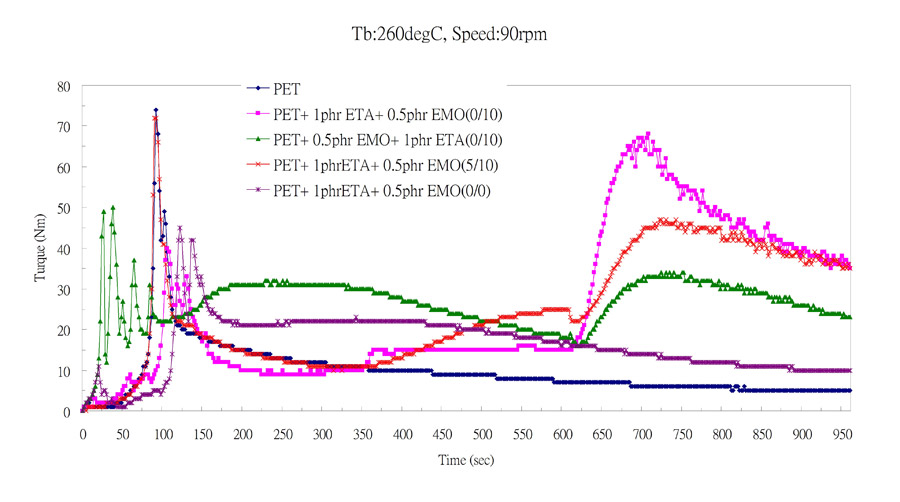

Innovative research and development

-

-

-

-

Super High Strength PET Strapping

Test Items

Test Metho ds

A-1%

B-2%

Tensile strength (kgf/mm2)

ASTM D638

T est speed : 50 mm/min

Specimen Type: Type I

45±2

47±2

Elongation degree (%)

ASTM D638

T est speed : 50 mm/min

Specimen Type: Type I

12~15

10~13

Dimensional

tolerances (mm)

Digital vernier

Width of packaging strap

16±0.2

16±0.17

Thickness of packagi ng strap

1±0.05

1±0.05

Split fract ure

Test for each m eter

Pass

Pass

Preface: The current technology of PET packaging strap enables production with 100% recycled material, which is in line with the policy of environmental protection around the world. Its cost is more than 30% lower than that of steel strapping. It also has the advantages of having fine appearance, does not rust, has good impact resistance, and is safe and convenient to use. It is expected to overshadow the steel strapping market and even the PP polypropylene strapping market in the near future. Currently, the PET packaging strap market is experiencing rapid growth.

Our team’s competitive edge lies in our threefold capability of mastering production technology, sales channels, and manufacturing equipment, which means the ability to provide all-round systematic and professional services with a deep understanding of market demand. Traditional equipment manufacturers can only manufacture equipment; they do not understand product manufacturing and marketing.

In contrast, our team attaches great importance to innovation, research, and development, as evidenced by the grants and innovation awards we have received for years from the government. We are striving to constantly improve our raw materials upgrading technology and product quality stability in order to develop Super High Strength PET Strapping

Our team’s competitive edge lies in our threefold capability of mastering production technology, sales channels, and manufacturing equipment, which means the ability to provide all-round systematic and professional services with a deep understanding of market demand. Traditional equipment manufacturers can only manufacture equipment; they do not understand product manufacturing and marketing.

In contrast, our team attaches great importance to innovation, research, and development, as evidenced by the grants and innovation awards we have received for years from the government. We are striving to constantly improve our raw materials upgrading technology and product quality stability in order to develop Super High Strength PET Strapping

Project No. 130509Small and Medium Enterprises Innovation Service Certification Supportive Program, “100% Recycled PET Toughening and Upgrading Technology”

Project No. 130509Small and Medium Enterprises Innovation Service Certification Supportive Program, “100% Recycled PET Toughening and Upgrading Technology” Contract number E10300018005-302Science and Technology Research and Development Program sponsored by the Ministry of Economic Affairs for Conventional Industry Technology Development (CITD): “Product Development Plan of Recycling Using PET to Produce High Tensile Packaging Strap”

Contract number E10300018005-302Science and Technology Research and Development Program sponsored by the Ministry of Economic Affairs for Conventional Industry Technology Development (CITD): “Product Development Plan of Recycling Using PET to Produce High Tensile Packaging Strap”

Description of Package Plant Export Equipment Manufacturing

Raw material ingredients/mixtures

Raw material drying system

Multi-sectional extension

Strapping winder

Quality inspection

Innovative research and development

Super High Strength PET Strapping

| Test Items | Test Metho ds | A-1% | B-2% |

| Tensile strength (kgf/mm2) | ASTM D638 T est speed : 50 mm/min Specimen Type: Type I |

45±2 | 47±2 |

| Elongation degree (%) | ASTM D638 T est speed : 50 mm/min Specimen Type: Type I |

12~15 | 10~13 |

| Dimensional tolerances (mm) Digital vernier |

Width of packaging strap | 16±0.2 | 16±0.17 |

| Thickness of packagi ng strap | 1±0.05 | 1±0.05 | |

| Split fract ure | Test for each m eter | Pass | Pass |